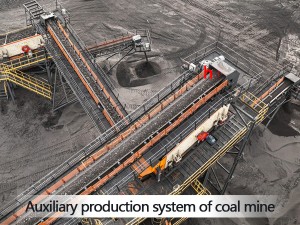

Coal Mine Auxiliary Production System Laser Range Sensor

Laser range sensors, also known as LiDAR sensors, play a critical role in the auxiliary production systems of coal mines. These laser range finder module sensors are used for various applications to enhance safety, improve operational efficiency, and support automation.

Here are applications of laser range sensor in coal mine auxiliary production systems:

1. Safety Monitoring

Obstacle Detection: Laser range sensors can detect obstacles and hazards in the mine, such as fallen rocks or equipment, helping to prevent accidents.

Personnel Tracking: TOF laser distance sensor can be used to monitor the movement of personnel within the mine, ensuring that workers are in safe areas and not in restricted or dangerous zones.

2. Environmental Monitoring

Deformation Monitoring: Super short range distance sensors can detect changes in the shape and structure of the mine, such as wall deformations or roof collapses, which are critical for maintaining the structural integrity of the mine.

Gas Concentration Detection: Some advanced laser ranging sensors can also be integrated with gas detection systems to monitor the concentration of hazardous gases like methane, providing early warnings to prevent explosions.

3. Automation and Navigation

Autonomous Vehicles: In modern coal mines, autonomous vehicles and machinery are increasingly being used. Laser distance sensors provide the necessary data for these vehicles to navigate safely and efficiently through the mine.

Robotic Systems: Robots used for tasks such as inspection, maintenance, and material handling can use laser range finder module to map their environment and avoid collisions.

4. Inventory Management

Material Volume Measurement: Laser rangefinder sensors can be used to measure the volume of coal stockpiles, helping to optimize inventory management and logistics.

Equipment Positioning: They can also be used to track the position and movement of mining equipment, ensuring that they are in the correct locations for efficient operations.

Data Collection and Analysis

Real-Time Data: Laser distance sensor provides real-time data that can be analyzed to make informed decisions about mine operations.

Integration with Other Systems

1. SCADA Systems: Laser measure sensors can be integrated with Supervisory Control and Data Acquisition systems to provide a comprehensive view of the mine’s operations.

2. IoT Platforms: They can be part of an Internet of Things platform, where data from multiple laser measurement sensors and devices is aggregated and analyzed to improve overall mine performance.

Maintenance and Calibration

1. Regular Maintenance: Like any other sensor, mini laser distance sensor requires regular maintenance and calibration to ensure accurate and reliable operation.

2. Calibration Tools: Specialized tools and software are used to calibrate the rangefinder sensors, ensuring that they provide precise measurements in the challenging environment of a coal mine.

Challenges and Considerations

1. Dust and Debris: The dusty and dirty environment of a coal mine can affect the performance of laser range sensors. Regular cleaning and protective measures are necessary.

2. Temperature and Humidity: Extreme temperatures and humidity levels can also impact laser range finder module performance. Super short range distance sensor needs to be designed to operate under these conditions.

3. Cost and Complexity: While laser range sensors offer many benefits, they can be expensive and complex to install and maintain. Cost-benefit analyses are often conducted to determine the feasibility of their implementation.

Seakeda laser range sensors are a vital component of the auxiliary production systems in coal mines, enhancing safety, efficiency, and automation. Their integration with other technologies and systems further amplifies their benefits, making them an essential tool in modern mining operations.

Post time: Jun-12-2025