Stacker Crane Long Distance Sensor

The stacker crane long distance sensor typically refers to a laser ranging module used in automated warehouse or storage systems, to detect the position, presence, or distance of objects over long ranges. These industrial laser distance sensors are crucial for precise navigation, collision avoidance, and accurate positioning within high-bay warehouses.

Key Features of Long Distance Sensors in Stacker Cranes

1. Laser Distance Sensors Method is phased or time-of-flight.

2. Measure distances up to 150 meters, even 200m.

3. High accuracy is ±1 mm to ±3 mm.

4. Used for detecting rack positions, end-of-travel limits, or pallet alignment.

Common Applications in Stacker Cranes

1. Positioning Accuracy: Ensuring the crane stops precisely at the correct rack level or bay.

2. Collision Avoidance: Detecting if another crane or obstacle is approaching.

3. End-of-Travel Detection: Preventing overtravel beyond the rail or rack limits.

4. Pallet Presence Verification: Confirming whether a pallet is present before retrieval or storage.

Example Models

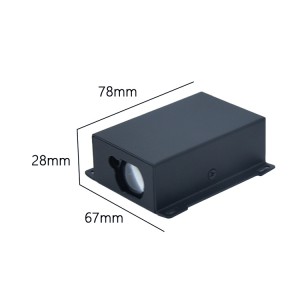

1. BA6A Laser Distance Sensor: For 150m long range and 1-3mm high precision detection.

2. PTWC-200H: TOF 350m laser sensor for height measurement with 200HZ.

3. ETYS-HF Lidar Sensor: 150m high frequency with 10KHZ, and 5cm-10cm accuracy.

Installation Tips

1. Mount laser distance sensors securely on the crane’s trolley or mast.

2. Use IP54 or IP67 rated protective housings in dusty or humid environments.

3. Calibrate regularly the long distance sensor to maintain accuracy.

4. Ensure clear line-of-sight for laser or avoid interference from reflective surfaces.

Let me know if you need help selecting or installing such a long range distance sensor!

Post time: Dec-11-2025